Alert Innovation offers groundbreaking micro fulfillment center technology to meet the demanding requirements of e-Grocery and other industry applications. We have over 50 patents issued or pending in support of these innovations.

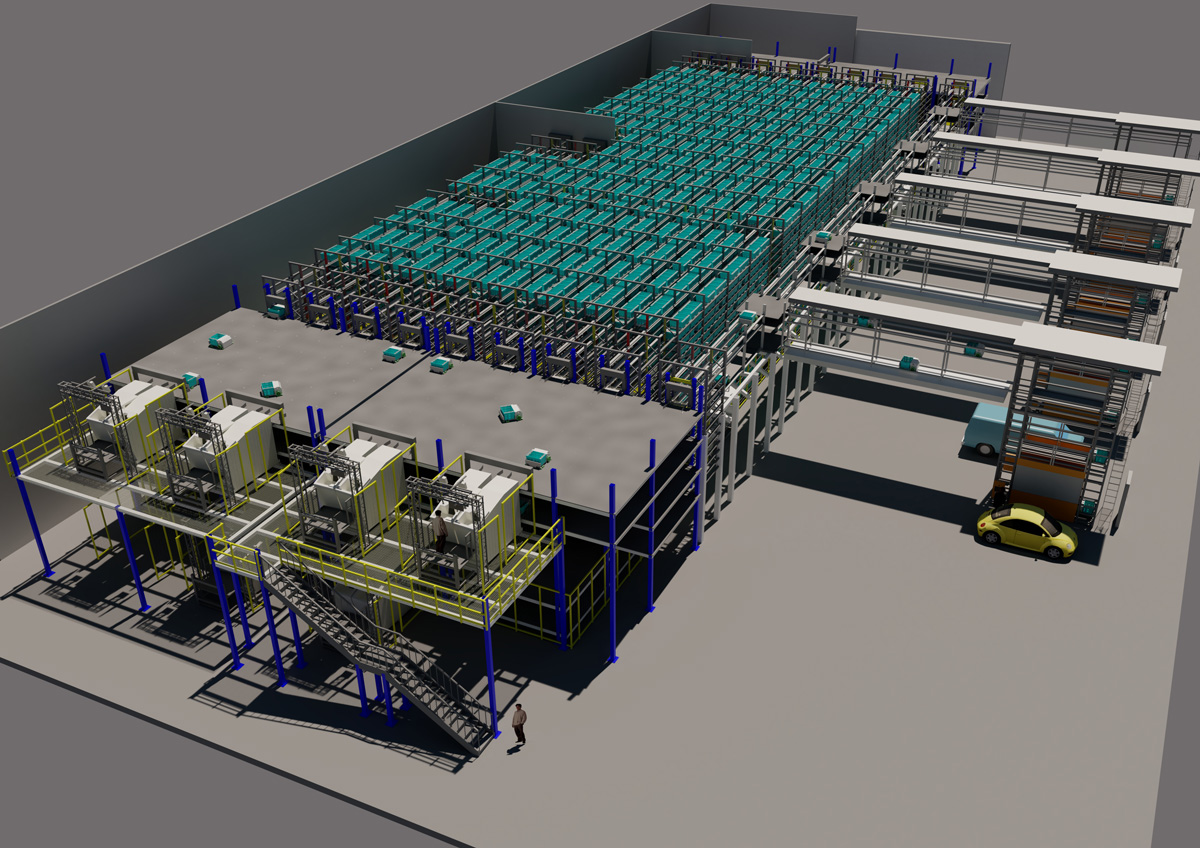

What makes the Alphabot System unique in the world is its ability to transform itself from a mobile robot, operating in two horizontal dimensions, into a vertical lift, move itself and its payload to any storage or workstation elevation, and then resume horizontal operation at that new elevation.

Our Flexible Mobile Robotics solution offers some significant advantages over Traditional Fixed Automation such as “shuttle” technology. When comparing micro fulfillment solutions, especially to automate inside a grocery store, please consider these Alphabot System advantages:

Handle all three temperature zones?

The Alphabot System can pick from ambient, chilled and frozen. Most other solutions require you to manually pick frozen items from your store floor.

Can the automation store completed orders in the system (in the correct temperature zone) until the customer is ready to pick up or the delivery driver arrives?

The Alphabot System stores the picked orders until the customer or delivery driver arrives at the store and then quickly dispenses all order totes. Most other solutions require you to dispense the order as soon as it is picked and requires you to have lots of freezers and refrigerators and racks outside of the automation system to store the completed orders which then need to be manually consolidated when the customer arrives.

Built-in order consolidation

The Alphabot System removes the consolidation step required by shuttle systems. Order totes can be dispensed to meet any business need without needed to consolidate multiple totes in an order.

Does your automation rely on chemical batteries to power the robots?

Alphabot Robots do not use chemical batteries (for example lithium-ion). Alert Innovation’s Alphabots use supercapacitors to power their movement. This removes the fire risk associated with charging batteries. Also, our supercapacitors fully charge in seconds as they travel vertically (rather than being sidelined for parts of the day to recharged.) As an added plus, supercapacitor powered robots are not impacted by cold temperatures, but rather perform even better in the chilled and frozen sections of our storage and retrieval systems.

Can the automation store products in sub-totes to enable significantly more SKUs in the system than totes and enable less than full case replenishment to further expand space available for additional SKUs?

The Alphabot System enables retailer to decant product at case quantity into full, one-half and one-third totes. We will soon be offering one-sixth and one-eighth subtotes to dramatically increase SKU count for smaller items.

Can the automation dispense orders directly to customers via a pick-up portal or to their car using the same robots used to store and retrieves totes?

Alphabot Robots can now dispense to a self-service pick up portal on the outside wall of the store for use by consumers or delivery drivers. Shortly, transit rails will enable our robots to leave the storage structure and move at elevation in delivering and picking up payloads at other locations within the operating facility or further into the parking lot.

Lower Total System Cost

In comparison to any shuttle system, the Alphabot solution costs less because the Alphabot robot performs all the functions of the shuttle robot, the lift, the conveyors and related transfers, and the workstation mechanisms that flow the totes through the workstation. Further, Alphabot features higher utilization during peak periods due to lack of captivity and random accessibility.

Higher Reliability

The Alphabot System is much more reliable than a shuttle system because the robots are the only moving part in the micro-fulfillment center. No Alphabot system has a single point of failure that can shut down the operation (such as lifts and conveyors). If a robot fails, other robots can route around it and the robot can be easily removed for repair at a convenient time. Alphabot offers a massively parallel, redundant architecture and this fault tolerance is critical in automating a grocery store.

Faster Speed

The Alphabot architecture enables high rates of product flow between storage and workstations, resulting in exceptionally fast order-completion times. Additionally, Alphabot currently enables human capable picking of 900 each per hour per workstation with higher pick speeds in development. Alphabot can pick grocery orders at peak demand from three temperature zones in 4 minutes average and 8 minutes 95th percentile.

Greater Space Utilization Efficiency

The Alphabot System currently uses single-deep tote storage, which utilizes roughly 65% of available storage volume. The ability of robots to climb enables unprecedented “transactional” density by stacking picking stations vertically. Overall, Alphabot space utilization cannot be matched when defined as throughput capacity (picking transactions per hour) per cubic feet of space used. Additionally, horizontal robot traffic is distributed vertically, requires less floor space and removes the congestion that shuttle systems face when having to move all bots on one level (or in the case of hive systems like Ocado or Autostore, on the top level).

Easier Scalability

Without any captivity of throughput assets with storage assets, The Alphabot System throughput and storage capacities can be scaled independently. The number of robots and workstations scale linearly with throughput, so it is a purely variable capex component. Modularity enables easy expandability. Put another way, Alphabot enables the retailer to meet growing eCommerce volume by simply adding more bots. Conversely, shuttle systems force the retailer to add storage capacity in order to get more bots and hence throughput.

Summary

In summary, micro-fulfillment is a hot topic for retailers and especially grocery retailers. The pressure is on for grocers to satisfy consumers’ ecommerce demands in a cost-effective manner. However, this article has pointed out how Alert Innovation’s patented Flexible Mobile Robotics approach provides distinct advantages over legacy traditional fixed automation like shuttles (for example from Knapp or Dematic) and HIVE systems (for example from AutoStore.)