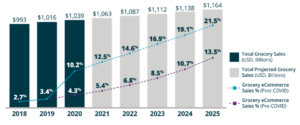

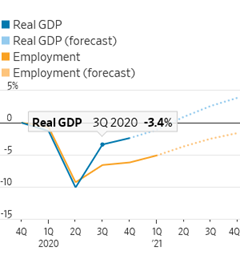

If you’re operating a Micro Fulfillment Center (MFC), you probably set it up in reaction to several unexpected changes. Your ecommerce order volume was exploding due to COVID. Your labor costs to manually pick orders were hurting your margins. You had to do something to control your order fulfillment costs.

The good news is that you did something. You replaced manual picking with automation. That change showed you that not only can ecommerce order fulfillment be profitable, you can also provide a much better service to customers when you have full control and visibility of inventory in your MFC.

Another bit of good news is that you are a leader. You are among the few who have firsthand experience operating an MFC. And as things have settled down, you can now use the time and experience you’ve gained to evaluate where you and your MFC stand. Is it doing all it can? Is it configured correctly? Is it being used optimally? Are you missing anything that can add value?

Defining an MFC

MFCs popped up quickly leading to a variety of definitions. For the purposes of this discussion, we will define a micro fulfillment center (MFC) as an automated system for grocery ecommerce order picking that is co-located at a supermarket. The MFC handles item storage, order picking and order dispense for a large percentage of items in an ecommerce order. Certain items are still picked from the floor. Some MFCs, such as the Alphabot® system by Alert Innovation, also handle completed order storage and automated order dispense to shoppers, which deliver additional labor savings.

Equipped with this definition, we’ll help you evaluate how to make sure you are getting the most from your MFC.

Did you Get the Size Right?

Any time you do something new, there’s a bit of guesswork. Add in the ecommerce order growth projections and trend disruption caused by COVID and you were basically flying blind when you sized your MFC. Thus, it’s possible you undersized your MFC.

The first challenge of sizing an MFC is determining the number of SKUs it can hold. Not every MFC is easily expandable, but with some systems you can increase item storage capacity independently of throughput, and vice-versa.

When sizing our Alphabot system, we encourage as much storage as possible in the initial design. This expands the assortment you can offer your shoppers and storage is cheapest to add at the initial build.

The other challenge with MFC system sizing is how many orders per day you can manage. You need to consider how fast you can get product into the system, how many items per hour you can pick both on average and at peak times and how fast you can get completed orders ready for shopper pickup or delivery.

With our Alphabot system you can efficiently increase orders per day from your MFC by adding robots to align with increasing demand. You may also be able to add order picking workstations or an automated picking arm.

Is Your MFC Reliable?

If your MFC requires frequent maintenance downtime or experiences failures that prevent order fulfillment, you’ll upset shoppers and won’t get the return you expected. To increase reliability of any system, the reduction in parts that need maintenance or can fail is paramount. This means eliminating lifts, conveyors, gears and other moving parts. Whatever the engineers can do to remove the risk of a single point of failure or the need for maintenance improves MFC reliability, lowers your cost of ownership and lets you serve your shoppers quickly and reliably.

Our Alphabot system was designed from the ground up with no moving parts in the structure to reduce maintenance and failure points. If there is an Alphabot failure, only that Alphabot and that specific location are affected. The rest of the Alphabot system will continue to operate.

As a reference, your MFC uptime should be over 99.5% with no major failures and a maintenance schedule that shouldn’t exceed 6 hours a month. If your mileage varies a lot from these benchmarks, you should think about MFC project 2.0.

Is Your MFC Achieving Maximum Labor Savings?

An MFC should cut your order-picking labor cost by 80% or more compared to manual picking. We’ve calculated millions of dollars in labor savings across a year at the store level. These savings are based on 80-100 hires that don’t need to be made when an MFC replaces manual order picking.

Our Alphabot system delivers additional savings from storing finished orders and automating order delivery to shoppers. These capabilities combine to improve labor savings by more than 40% beyond a standard automated picking system.

Does Your MFC Eliminate Order Delivery Costs?

Last mile costs are an ecommerce profit killer. Target estimates they save 90% when a shopper picks up an order at the store. Average last mile delivery costs are estimated at around $10 per order.

You can eliminate last mile delivery costs through marketing programs that encourage at store pickup. You can further reduce delivery costs and time through automated order dispensing, which, as offered by our Alphabot system, removes the labor of associates consolidating and delivering orders to shoppers.

Is Your MFC Causing Warehouse Congestion?

Most MFCs hold completed orders outside the system. This approach requires additional storage locations to stage those orders. Since most orders also contain frozen and refrigerated items, secondary refrigeration units are needed.

The added storage and refrigeration equipment, combined with order consolidation, leads to warehouse congestion. And failing to keep products in their proper temperature range while picking, staging and transferring will impact product quality and shelf life.

The Alphabot system uniquely supports three temperature zones including frozen. Items and completed orders are stored in the system in their appropriate temperature zone until ready for customer pickup or delivery to home. This approach maintains maximum freshness, food safety and customer satisfaction. The Alphabot system also automates the delivery of completed orders to shoppers. By adding completed order storage and automated order dispense to the system, warehouse congestion is eliminated.

Is Your MFC delighting Your Shoppers?

Two of the biggest shopper complaints of manual ecommerce order picking (aside from picking carts clogging store aisles) are out of stocks and substitutions. It’s common for as little as 65% of a shopper’s order to be available from in store inventory through manual picking. Since an MFC is a closed system, both out of stocks and substitutions can be eliminated through near-perfect inventory visibility.

If your MFC is still having out of stocks and requiring substitutions, you need to review your methodology for determining the assortment that gets loaded into the system and how you determine and communicate available inventory to your shoppers.

Is Your MFC Generating All the New Sales it Can?

When an MFC is first installed, the focus is on labor savings. But MFCs can fulfill eight to ten times as many ecommerce orders as manual pickers, offering you the opportunity to capture new ecommerce business.

Like the stores they support, the more orders processed by your MFC, the better the ROI. Make sure you are using your efficient MFC to increase ecommerce sales and market share, not to just satisfy existing ecommerce order demand.

Our Alphabot system offers the ability to add Alphabot robots to increase order throughput. This is an economical way to capture more ecommerce sales from an existing MFC.

Improve the Value Your MFC Delivers

An MFC is a first step in an automation journey. As defined, it handles product storage, order picking and order dispensing for pickup or delivery. It can also automate order dispensing, which rewards you with significant additional labor savings, in some cases 20% or more.

What about a better process to break down cases to place items into your MFC? Have you considered how much labor you can save by automating inventory replenishment?

Are you getting full order picking volume from your MFC? For example, could you benefit from picking overnight but have trouble staffing? An automated picking arm might be a valuable upgrade.

Is Your MFC Future-proof?

As we’ve learned with the unexpected explosion of grocery ecommerce, you can’t predict the future. But you can select an MFC that is designed to be future-proof by design.

Your MFC should be able to expand capacity, increase order throughput and add new automation elements easily and economically as technologies evolve. You can’t anticipate what will change. You can however select an MFC that’s designed for change.

Summary

As MFCs and their supporting automation capabilities continue to expand, keep an eye on your labor costs and where you have delays today. There may be ways to get even more value from your MFC.

The combination of a future-proof MFC and your store locations gives you the tools you need to be a winner in this new game.

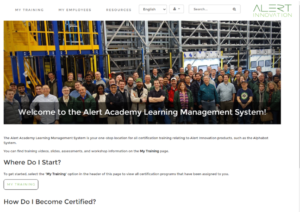

Alert developed the Alert Innovation Academy to train existing retail employees to work with the Alphabot system. Alert Innovation Academy has a career development trajectory that graduates workers from operators to robotics tech 1, tech 2 and even systems operation manager. Associates can start stocking shelves and become a robotics expert!

Alert developed the Alert Innovation Academy to train existing retail employees to work with the Alphabot system. Alert Innovation Academy has a career development trajectory that graduates workers from operators to robotics tech 1, tech 2 and even systems operation manager. Associates can start stocking shelves and become a robotics expert!